01

/01

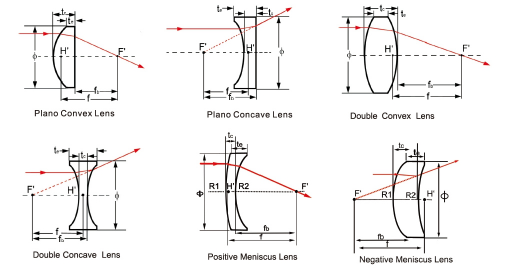

A plano concave lens is a lens that is flat on the one side and concave on the other. Plano concave lenses converge parallel light, correct the deflected light and convert point light sources into parallel light.

Attribute:

Main materials: all kinds of high-quality environmental protection optical glass. Contains: optical glass H-K9, H-BAK7, quartz, fused silica, sapphire, etc.

Focal length: ±5mm~1000mm±2%

Thickness tolerance: ±0.2mm

Size: 6mm-300mm

Surface type: λ/10~λ/2

Surface quality: 10/5~80/50

Eccentricity: <3arcmin

Effective aperture: >90%

Chamfer: <0.2*4.5°

Coating: according to customer requirements

Introduction of Plano-Concave Lenses

A plano concave lens is a lens that is flat on the one side and concave on the other. Plano concave lenses converge parallel light, correct the deflected light and convert point light sources into parallel light. When light enters from the concave surface of the plano concave lens, the light will converge to a point on the concave surface. When a point light source enters from the plane of the plano concave lens, the light will be turned into a parallel beam. The focal length of a plano concave lens can vary depending on wavelength. Plano concave lenses can be used in transmitters, detectors and lasers.

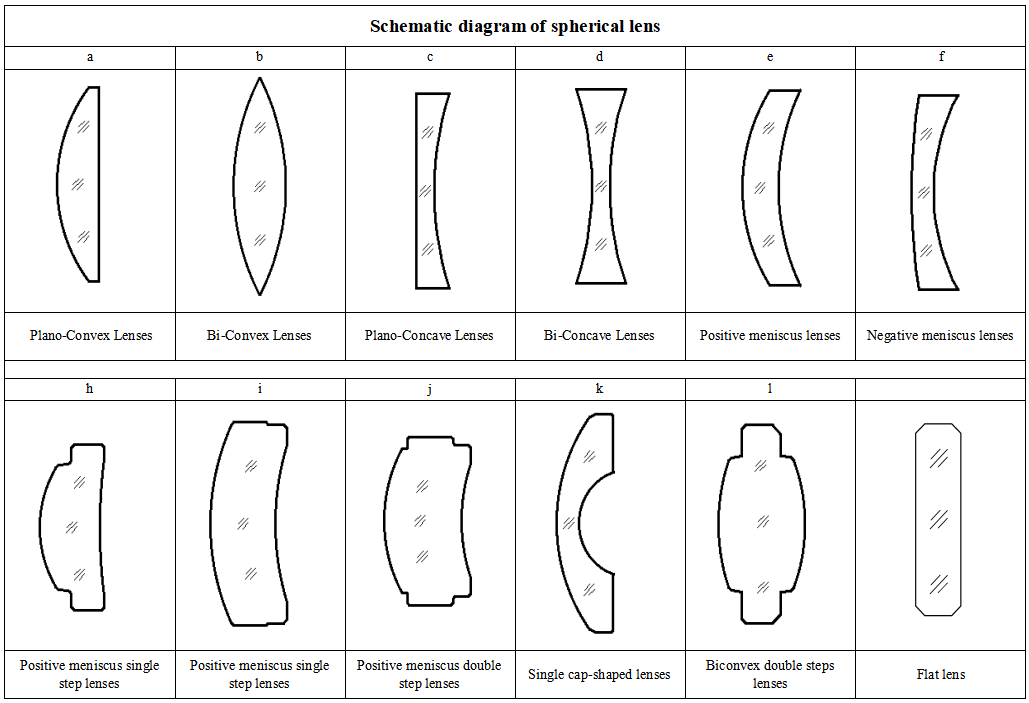

Spherical lens features

Spherical lens processing types

Plano-convex lenses, double-convex lenses, plano-concave lenses, double-concave lenses, positive meniscus lenses, negative meniscus lenses, flat lenses, single-cap lenses, double-convex double-step lenses,

Plano-concave lens scatters parallel light outward. The focal length of the plano-concave lens is negative, and the spherical aberration is also negative, which can be used to correct the aberration, spherical aberration, coma, and distortion of other lenses. Similar to a plano-concave mirror, the sides generally face the far object surface or infinity. The plano-concave lenses produced by Dingxinsheng Optical are usually made of K9 glass, and their anti-reflection coating is aimed at the wavelength range of 400-700 nanometers. There are also UV quartz as the base material for processing. When UV quartz is used as the base material, it has good transmittance and low thermal expansion coefficient in the ultraviolet region, and can be coated with UV AR film for use in special circumstances.

Production Capacity Sheet

| Category (Diameter) | Thickness Tolerance | Surface Precision | Surface | Eccentricity | Abrasion Degree |

| φ2~φ3.5 | ±0.015 | 0.3 | 10xMicroscopic test: the center is flawless, and the edge is 20-10 | 120″ | 40-300 |

| φ3.5~φ10 | ±0.015 | 0.3 | 45″ | 40-488 | |

| φ10~φ25 | ±0.02 | 0.3 | 15-20 | 30″ | 40-488 |

| φ25~φ40 | ±0.02 | 0.3 | .20-10 | 30″ | 40-488 |

| φ40~φ55 | ±0.02 | 0.5 | 40-20 | 30″ | 40-488 |

| φ55~φ80 | ±0.02 | 0.5 | 40-20 | 30″ | 40-300 |

| φ80~φ150 | ±0.03 | 1.0 | 40-20 | 30″ | 40-300 |

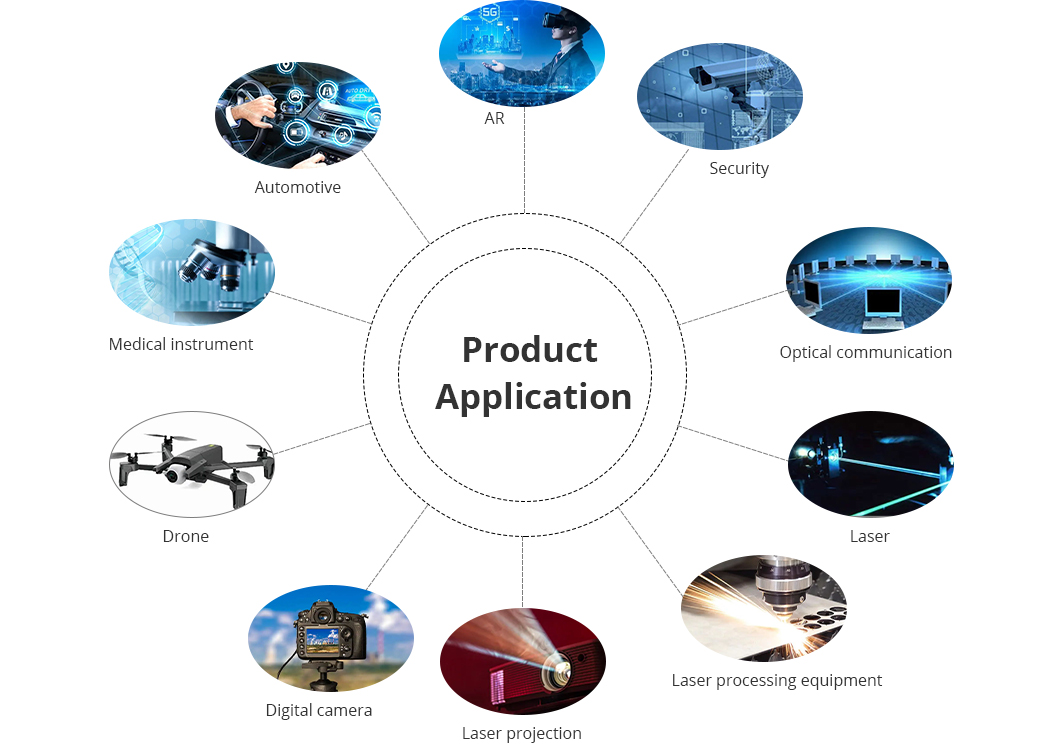

Application

Glass lenses have a wide distribution of refractive index and dispersion, and have good adaptability to temperature and environment. They are widely used in high-end optical lenses, such as digital cameras, security, automotive, optical communications, laser projection, medical, unmanned machine, AR, etc.

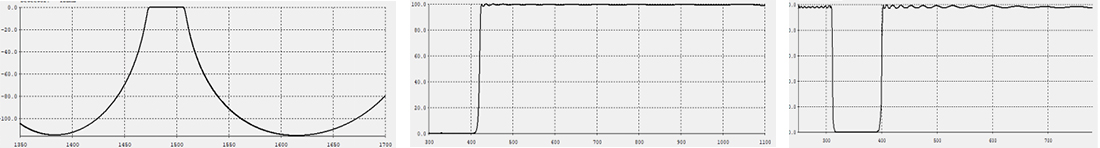

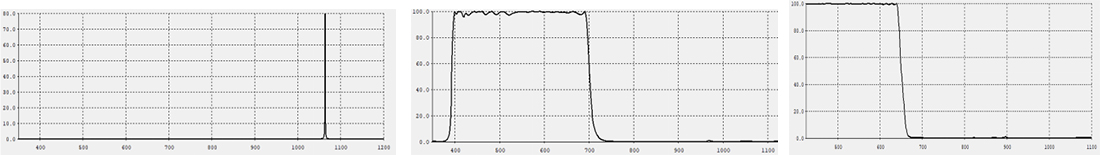

Standard Optical Coating

We provides high-quality coating services. Our company has successively introduced several Optorun coating machines and SHINCRON sputtering coating machines, with standard &high quality coating technical capabilities. We can customize the coating according to the individual needs of customers, and provide free design and testing

| Coating series | |||||

| Antireflection coating | 400nm-1000nm, R<=0.5% | ||||

| High reverse coating | 420nm-720nm, R>=98% | ||||

| Metal coating | gold coating, silver coating, aluminum coating etc | ||||

| Spectro coating | neutral spectro coating, PBS coating, dichroscope coating etc. | ||||

| Filter coating | long wave pass filter, short wave pass filter, bandpass filter, narrow bandpass filter etc | ||||

| Functional coating | waterproof coating, anti-fouling coating、UV-IR-CUT、super hard coating, EMS anti-static coating, ITO conductive coating etc | ||||

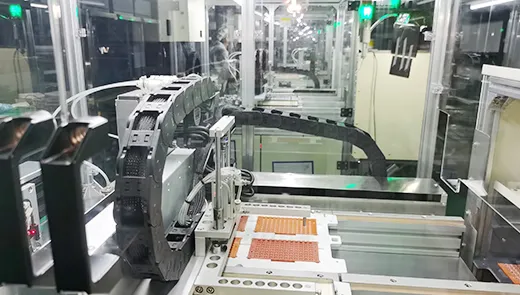

Workshop equipment

We are looking forward to establishing long-term cooperative relations with customers around the world on the basis of trust and mutual benefit. Please feel free to contact us for further information. We sincerely welcome you to our factory.

Copyright © Jiangxi High-Resolution Optoelectronic Co., Ltd. All Rights Reserved | Sitemap