01

/01

A biconvex lens is a lens with convex surfaces on both sides, with similar radii of curvature on both sides.

Attribute:

Materials: High quality and environment-protection optical glass

Include:H-K9, H-BAK7、quartz, fused silica, sapphire etc

Focal length: ±5mm~1000mm±2%

Thickness tolerance: ±0.2mm

Size: 6mm-300mm

Surface type: λ/10~λ/2

Surface quality: 10/5~80/50

Eccentricity: <3arcmin

Effective aperture: >90%

Chamfer: <0.2*4.5°

Introduction of Biconvex lenses

A biconvex lens is a lens with convex surfaces on both sides, with similar radii of curvature on both sides. Lenticular lenses are symmetrical to minimize spherical aberration, coma, distortion and aberrations. The larger the conjugate ratio, the larger the resulting aberration. One side of the lenticular lens is used to correct polarized light. The other side focuses parallel light into a small spot. Lenticular lenses converge, transmit light, and can transmit images to other optical systems. Commonly used in imaging relay systems and object imaging with limited conjugate distance.

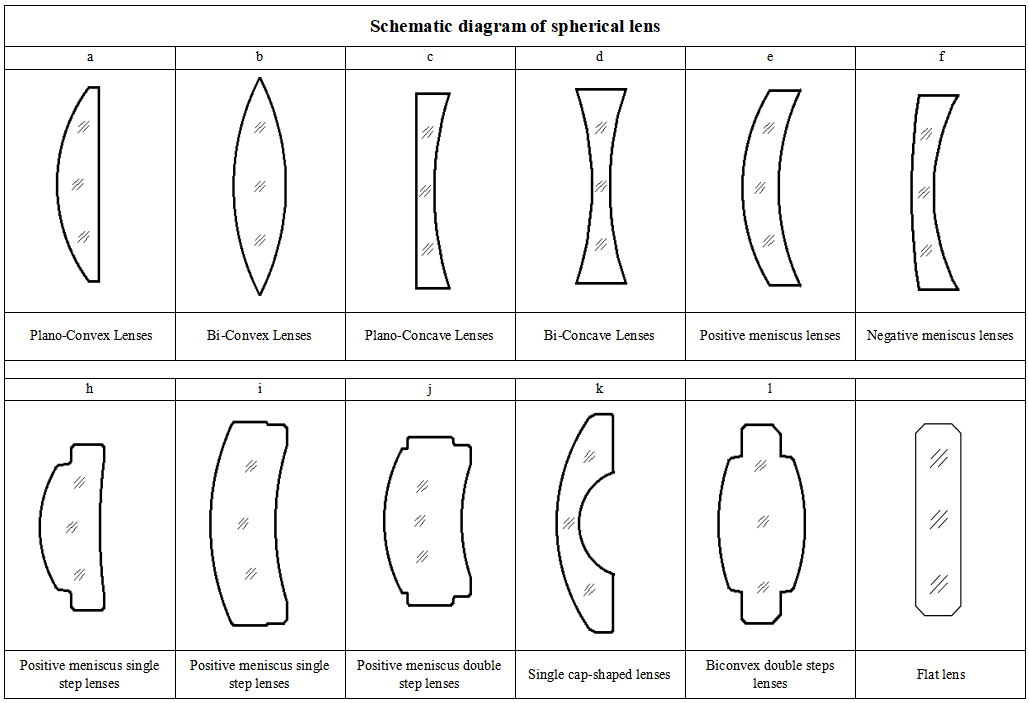

Spherical lens features

Spherical lens processing types:

Plano-convex lenses, double-convex lenses, plano-concave lenses, double-concave lenses, positive meniscus lenses, negative meniscus lenses, flat lenses, single-cap lenses, double-convex double-step lenses

Lenticular lenses have a positive focal length and can also focus parallel beams. Since the front and rear surfaces of the lenticular lens are convex spherical surfaces with equal radii of curvature, the lenticular lens can significantly reduce spherical aberration and improve coma aberration and distortion in applications where the object and image distances are equal or approximately equal. Lenticular lenses introduce minimal aberrations when the conjugate ratio is between 5:1 and 1:5.

Production Capacity Sheet

| Category (Diameter) | Thickness Tolerance | Surface Precision | Surface | Eccentricity | Abrasion Degree |

| φ2~φ3.5 | ±0.015 | 0.3 | 10xMicroscopic test: the center is flawless, and the edge is 20-10 | 120″ | 40-300 |

| φ3.5~φ10 | ±0.015 | 0.3 | 45″ | 40-488 | |

| φ10~φ25 | ±0.02 | 0.3 | 15-20 | 30″ | 40-488 |

| φ25~φ40 | ±0.02 | 0.3 | .20-10 | 30″ | 40-488 |

| φ40~φ55 | ±0.02 | 0.5 | 40-20 | 30″ | 40-488 |

| φ55~φ80 | ±0.02 | 0.5 | 40-20 | 30″ | 40-300 |

| φ80~φ150 | ±0.03 | 1.0 | 40-20 | 30″ | 40-300 |

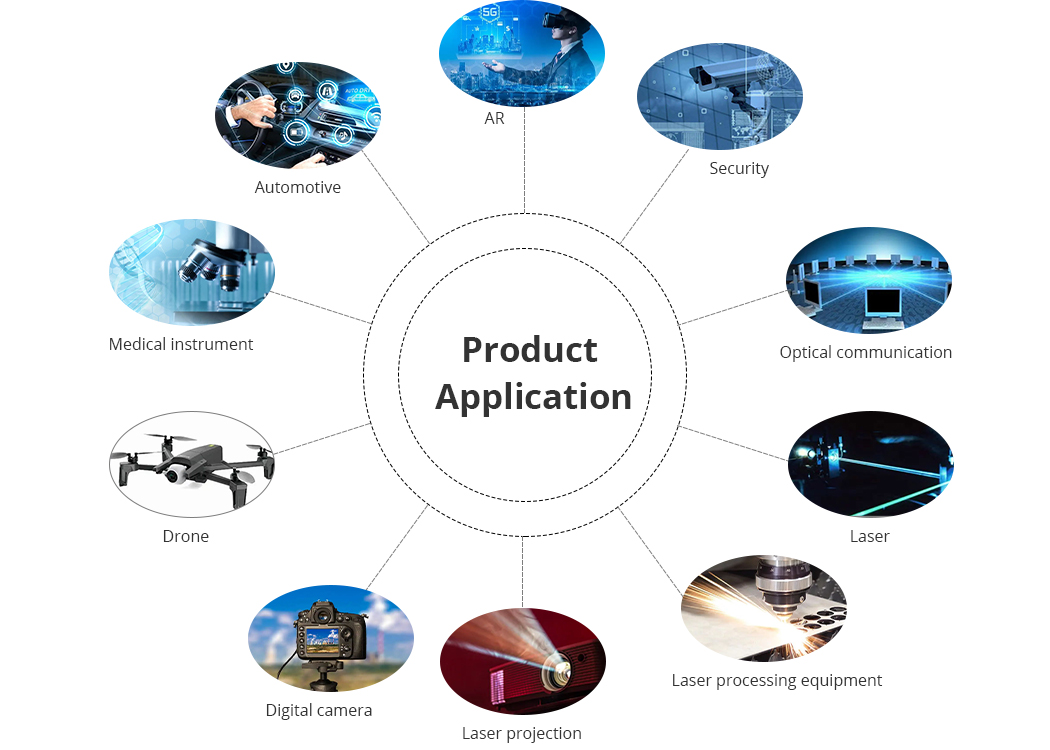

Application

Glass lenses have a wide distribution of refractive index and dispersion, and have good adaptability to temperature and environment. They are widely used in high-end optical lenses, such as digital cameras, security, automotive, optical communications, laser projection, medical, unmanned machine, AR, etc.

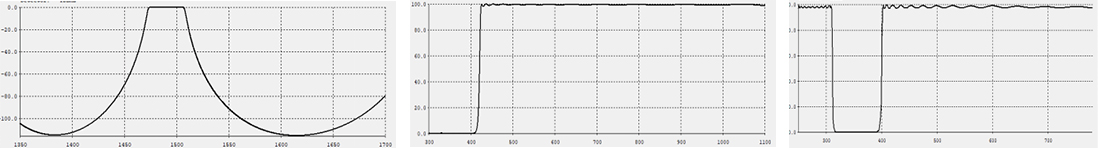

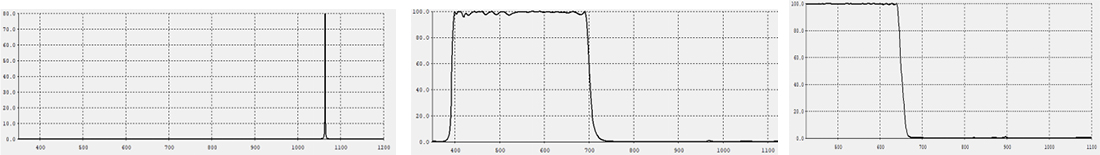

Standard Optical Coating

We provides high-quality coating services. Our company has successively introduced several Optorun coating machines and SHINCRON sputtering coating machines, with standard &high quality coating technical capabilities. We can customize the coating according to the individual needs of customers, and provide free design and testing

| Coating series | |||||

| Antireflection coating | 400nm-1000nm, R<=0.5% | ||||

| High reverse coating | 420nm-720nm, R>=98% | ||||

| Metal coating | Gold coating, silver coating, aluminum coating etc | ||||

| Spectro coating | neutral spectro coating, PBS coating, dichroscope coating etc. | ||||

| Filter coating | long wave pass filter, short wave pass filter, bandpass filter, narrow bandpass filter etc | ||||

| Functional coating | waterproof coating, anti-fouling coating、UV-IR-CUT、super hard coating, EMS anti-static coating, ITO conductive coating etc | ||||

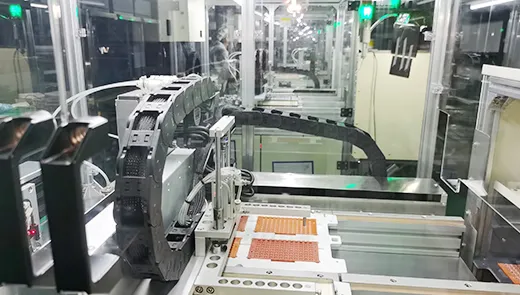

Workshop equipment

We are looking forward to establishing long-term cooperative relations with customers around the world on the basis of trust and mutual benefit. Please feel free to contact us for further information. We sincerely welcome you to our factory.

Copyright © Jiangxi High-Resolution Optoelectronic Co., Ltd. All Rights Reserved | Sitemap